The Landscape Services department at Michigan State University (MSU) maintains approximately 2,000 acres of the 5,200-acre East Lansing, MI campus. The department employs 60 full-time employees and more than doubles its workforce during the growing season with full-time temp, part-time, and student positions.

Landscape practices are constantly evolving, and over the past decade, we have leveraged more data and technology to improve daily decision-making and augment workforce capacity through equipment innovations. One significant area of focus has been testing and deploying robotic lawn mowers with the goal of shifting our team members to other tasks while the robotic mowers handle lawn maintenance.

After eight years of testing and deploying robotic lawnmowers, we have learned a lot!

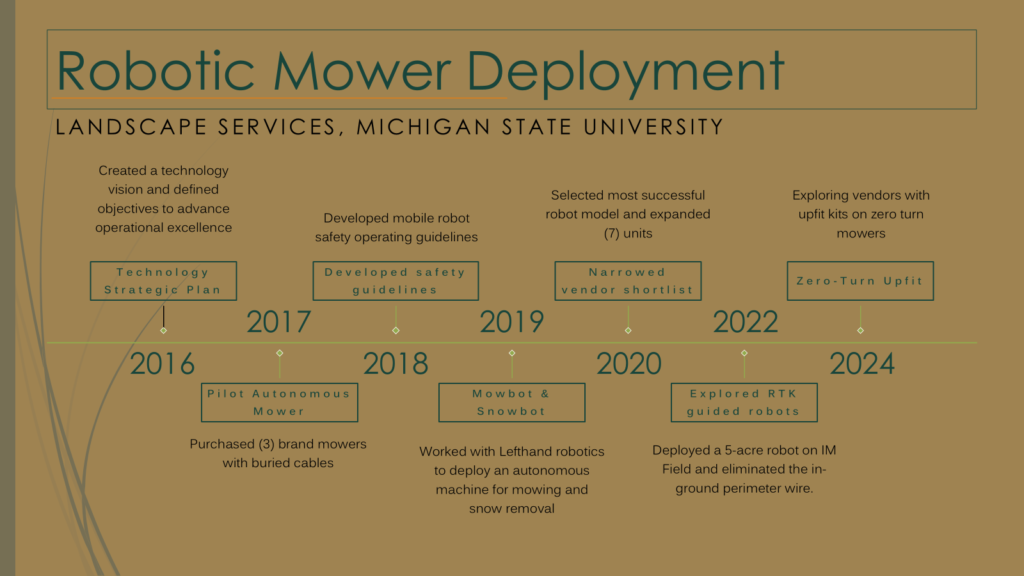

It has been a calculated journey of assessing the business case and working with multiple vendors to deploy their products consistently and safely in a campus environment. We created a technology strategy for Landscape Services in 2016 that included three key areas of focus:

- Deploying iPhones/iPads to our workforce and expanding the use of GIS mobile applications to provide information for our team members, but also have them enter their tasks completed daily.

- Building operationally focused dashboards to help visually connect the work our staff was completing and how that aligned with the department’s goals and objectives.

- Deploying and testing robotic lawn mowers with the goal to get to scale in the next decade.

What Is The Business Case?

The primary goal is to deploy an autonomous, battery-powered lawn mowing fleet that can operate at night while students, faculty, and staff sleep, thus minimizing disturbances to teaching and research activities in addition to reducing our carbon footprint.

In 2016, we began with a small pilot program in the Landscape Services department, deploying over 100 iPhones and iPads and a technology ecosystem built on GIS platforms. This better connected our employees with the assets they manage daily (e.g., trees, planting beds, equipment, pathways). An unforeseen benefit of this pilot was the creation of a culture of trust and empowerment, as well as enhanced planning and implementation for daily maintenance. The video below explains more.

Due to the pilot program’s success, we scaled up the mobile device deployment strategy in 2018 across the facilities organization, distributing around 1,100 mobile devices. This created a technology ecosystem focused on improving access to information in the field where our team members make daily decisions.

The mobile devices and the backend technologies we implemented helped upskill our workforce and prepared us for robotic deployments. Many of the robotic brands we tested and deployed had mobile applications to control or modify the robots’ schedules. This was a seamless transition because our staff was already familiar with smartphone applications.

Deployment of Robotic Mowers

In 2018, we deployed the first commercially available robotic mower and snow removal machine. The unit was outfitted with a front PTO to operate a 50” mower deck during the summer and converted to a broom for snow removal during the winter months. This deployment prompted the development of safety guidelines for using robotic machinery in a campus environment, guidelines we could not find among our peers in educational facilities.

In 2020, we capitalized on the reduced campus activity due to the COVID-19 pandemic by deploying seven Husqvarna Automowers and two Kress 5G wireless line-striping robots. “It is our commitment to the university and community to provide the highest level of service while supporting and growing this living, learning laboratory,” said Jeremiah Saier, landscape services GIS planner/inspector/analyst. “There is a fantastic opportunity right now to exercise how efficient and relevant we can be during tough times—embracing the challenge and leading by example.”

Saier added, “Changing the way we do our jobs is motivating, contagious, and energizing—all things we need right now. Using our Landscape Management Plan estimator, we predict roughly eight to nine months of utilization (1.5 growing seasons) will meet our full ROI (return on investment) potential. Once we’ve hit our ROI goal, we’ll save the university approximately $2,100 per season at the ISTB courtyard alone for a much nicer, environmentally friendly space.”

Scaling Up in 2024 and Beyond

In 2024, we are exploring multiple vendors who have upfitted the autonomous technology onto existing zero-turn mowers, making them autonomous. “We need to get to scale. Our team mows 400 acres of turf, 38 weeks a year. We began with the mission of deploying battery-powered units around classroom facilities to reduce noise pollution and help our community focus on their research and learning. But we are continuing to seek out technology vendors to help us scale up our fleet of mowing equipment.” said Matt Bailey, landscape services manager.

At the end of the day, technology is simply a tool to solve a problem. When you identify the problem, it is important to consider the cultural implications of how that technology may not only mitigate the problem but also positively impact the daily lives of your employees. Robotic mowers will help improve efficiency, but imagine outfitting that robot with other technology which can asses turf health, identify wet areas from broken irrigation heads, or any number of other landscape issues that you can dream up. We certainly could outfit existing mowing fleets with this technology, but it is the strategy that we all can dream up that will drive future innovation and advance our industry. We cannot wait to see what to come up with next!

Adam Lawver is assistant vice president of infrastructure, planning, and facilities at Michigan State University. He can be reached at lawverad@msu.edu.

Power Tools

Seeks to engage multiple voices from among FM ranks to bring fresh insight and real knowledge from the trenches on what’s working in planning and implementation for energy-related projects and innovations. To contribute, contact publications@appa.org.

See all Power Tools.