“……there are known knowns—these are things we know we know. We also know there are

known unknowns—that is to say, we know there are some things we do not know.

But there are also unknown unknowns, the ones we don’t know we don’t know.”

This quote, by former U.S. defense secretary Donald Rumsfeld during a 2002 press conference, was in response to a reporter’s question regarding the war in Iraq. He might as well have been expressing a truism about construction project risk management.

Let us assume, for the purposes of illustration, that a college’s mission is to construct a new 15,000-square-foot library and technology center on vacant space that previously housed a now demolished and cleared vehicle maintenance garage and parking area. The college recently received a $13 million grant from the estate of an alumnus for the specific purpose of constructing this sorely needed facility, which will feature these seven items:

- Housing for a collection of 23,000 books and printed materials

- 100 individual workstations with computers

- 15 group work/study rooms

- 20 individual study rooms

- Office/workspace for 12 library staff, including interns and volunteers

- A classroom/meeting room for community and college use

- An outdoor learning/study area

These features, along with the project’s size, campus location, and budget, comprise the “known knowns”—the things we know about our project.

The new Kirkland Elementary School building (discussed in this article and the previous article in this series) features pre-engineered steel framing. Author Michael Ellegood: “This type of construction was selected because of the remote location of Kirkland. Conventional ‘stick built’ construction would have been cost prohibitive.”

But there are known unknowns as well. For example, because the site is the former location of the college vehicle maintenance facility, it may be contaminated with hydrocarbons. Remnants of abandoned foundations, live utility lines underground, and site drainage may also be an issue. We know that these will require further investigation before the work scope is finalized.

As in every project, we can also expect surprises—the true unknown unknowns. And, if not caught early in the project delivery process, they can be costly and time consuming and can even result in project failure (defined here as a significant cost increase, a major schedule delay, or a project that fails to meet shareholders’ expectations).

A formal risk management process conducted early in the project and repeated at various intervals in the pre-construction process can help to avoid very costly construction changes and project delays.

The formal risk analysis: a hypothetical

A formal risk analysis should be conducted as a meeting of the project delivery team. Include documentation and follow-up as appropriate. It is important to recognize that a risk management analysis is not a “one and done.” Best practice recommends a formal risk analysis at the start of a project, at the end of the planning or initial phase, and at any time that a potential risk is recognized. A formal risk analysis will:

- Identify the risk,

- Identify means and methods of eliminating the risk,

- Identify means and methods of mitigating project impact if the risk cannot be eliminated, and

- Identify whose responsibility it is to manage this risk.

Consider a totally hypothetical example involving our college library project:

Library technology continues to advance, leading to the development of robotic publication file and retrieval systems. Based on artificial intelligence, these systems store and retrieve hardcopy research materials robotically in a matter of minutes once a user identifies the needed material. They are said to reduce staffing needs, prevent misfiling of documents, and allow materials to be stored in less space than in manual systems. However, they require infrastructure, procurement of long lead items, software installation, and staff and user training. Since the project stakeholders have specified a state-of-the-art library and technology center, a robotic file and retrieval system is desired to be integrated into the stack system.

To deliver the library, we need to know the requirements of this automated system, including floor loading, power (voltage, amperage, and location), and what elements of the system need to be built into the structure.

Moreover, since we don’t yet know just how long it will take to procure, manufacture, and receive some of the equipment, we need to investigate further with potential vendors and reflect in the schedule. To integrate this robotic system into the larger project and not generate an impact on schedule:

- The library staff must select the system and obtain approval from the college administration.

- The vendor/manufacturer must identify the building components needed to support the system (structural, electrical, mechanical, etc.) and identify the required lead time.

- If appropriate, the project delivery team must recommend early procurement of the system.

The example above outlines the risk analysis process.

While it is essential to have a formal process, it is equally important to always be aware of potential issues that might occur as the project progresses and causes what could be an adverse impact. I knew an excellent project manager for major public infrastructure projects who used to ask his team members at every project meeting, “Does anyone see any risks?”

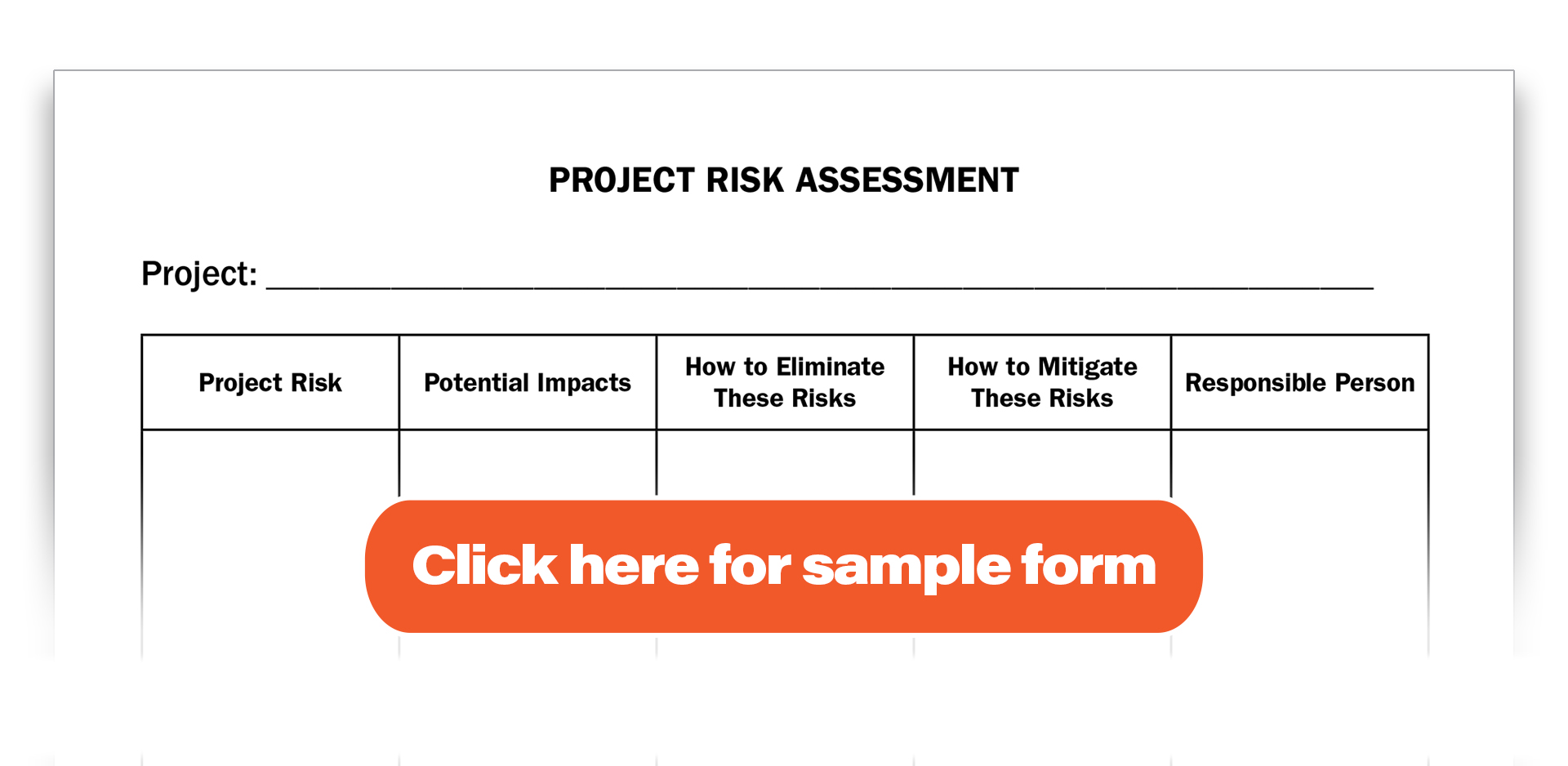

You might create a simple form for memorializing the risk management analysis as demonstrated below.

Before starting the risk analysis, it is important to recognize the five top manageable causes for capital projects to be delayed or go over budget:

- Inability to obtain rights-of-way or real property (In this case, since the college owns the property, this will not apply.)

- Utility interferences (There may be underground or overhead utilities on our site. We don’t know.)

- Permitting issues causing delays or re-work (Being a separate municipal organization, we probably do not have to concern ourselves with land use [zoning], but we will need building permits from the local municipality; these can take a significant amount of time and the cost of compliance can be expensive.)

- Political and/or public objection (This may be a concern if the proposed site abuts a residential community or if outspoken faculty or student groups express concern over a project feature.)

- Underground conditions (These can include poor soil, contaminated soil, hazmat underground, old foundations, anything underground that may cause construction delays.)

These causes are generic and applicable to most projects, but each capital project is somewhat unique and has its own associated risks. The idea here is to identify the risks and to develop a plan to eliminate or mitigate these risks.

On the hypothetical project outlined above, we know that the site was a former vehicle parking and maintenance area. We can expect to find contaminated soil, perhaps abandoned underground utilities or facilities, possibly old foundations, or perhaps even a covered maintenance pit or fuel tank. To avoid construction surprises, we need to conduct extensive underground and soils investigations and utility mapping. Then we must mitigate what the investigations found or identify them on the plan assembly (the plans, special provision, specifications, and estimate) so that they can be part of the initial contracted bid and not a potentially expensive change order negotiated later.

This last sentence is key to delivering a successful project. The designer and preconstruction team should identify and include in the initial bid anything that may cause a project change order during construction. During the design and preconstruction contract phase, the owner and preconstruction team has almost unlimited negotiation power; once the contract is let, the team is almost always at the mercy of the contractor.

What about changes?

Original (left) and new (right) power poles supplying Kirkland Elementary School. Author Michael Ellegood describes these as “known unknowns” of the project. The original pole was located directly in front of the proposed main entrance to the new school building. Ellegood and colleagues “coordinated with the power company to relocate and to underground the power lines in front of the building. Power company records showed that the pole was 88 years old and scheduled for replacement; they rearranged the schedule to expedite the replacement. The school paid for under-grounding the lines, and the power company replaced the pole.”

Despite our best abilities to identify and manage risk during the early design phases, changes during construction do occur and, typically, are far more costly than if they had been identified in the base contract. As a rule, and to aid in budgeting, construction change orders on average equal about 10% of the base contract price, though the actual amount can be much higher, depending on variables including weather, location, and project complexity. The contingency percentage is a pure judgment call. In any case, change order costs should be managed as part of a contingency fund that the “owner” (for example, the institution or school district) budgets and appropriates.

How do you, as the individual charged with delivering the project, identify every possible issue that can go wrong and develop a plan to avoid costly changes? Very simply, you probably can’t catch them all; certainly, force majeure conditions like weather disasters can’t be reasonably forecast. But you can and must identify as many as you can. Here are some recommendations:

- Don’t attempt to identify all contingencies by yourself. Get your project delivery team and key stakeholders together and brainstorm what might go wrong and how to eliminate or mitigate the risk. Each member of your team will have a different perspective drawn from different experiences, and the collective “group think” will bring a more comprehensive perspective than one or two experts thinking alone.

- Consider items’ lead times, especially those that are essential to make the project work but might take a long time to procure, manufacture, and deliver. (In the case of the robotic library system, it might be air conditioning equipment, library furnishings, or computer equipment including routers, printers, and ancillary equipment. You may not know what these items are, but your vendors, library staff, or members of the design team or maintenance staff may know.)

- Consider what might happen during the period between the project’s initial concept and its final delivery. For example, in the world of technology, two years is a long time. Will the design provisions for technology in the new facility meet what might happen during the two-year project delivery period? What about provisions for AI? Will that emerging technology need some sort of special facility construction? Can these be envisioned?

- Consider security. What sort of physical and technological security will be needed? Will technology and cybersecurity standards from NIST (the National Institute of Standards and Technology) and/or ISO (the International Organization for Standardization) be required, and will compliance with these standards require consideration in the physical facility?

- Beware of the “good idea fairy” who seems to be involved in every project. These are the folks who, like Halley’s Comet, swoop in from outer space and “suggest” ideas that are not in the agreed-upon scope. The project initiation form protocol, discussed in the first article in this series, can help dissuade this kind of influence. Beware also of changes in senior administration; often, new leaders want to put their stamp on projects, causing mid-project changes.

- Establish a project advisory committee consisting of interested faculty, representatives of the community, student representation and, most important, someone from facility maintenance. The purpose of such a committee is to provide input and suggestions from users, interested individuals, as well as the team that will have to operate and maintain the building throughout its life. The committee’s function is not to design or have even meaningful say in the project but to provide the project delivery team with advice from a user/maintainer/community perspective. An advisory committee can also help gain and maintain community acceptance, and its broad and differing perspectives may be useful in identifying potential risks to project success.

- Consider adjacent land use and the impacts that the project may have on neighboring properties. If, for example, our proposed library project abuts residential properties, one might conclude that it’s a far more compatible use of the land than the previous vehicle maintenance facility. However, if the library is multi-story, neighbors might be concerned about library patrons looking into their backyards or even into their homes. They may object to the building blocking their views; they might be concerned about increased traffic from library users. Good community relations are vital for any project, particularly one that will become an essential community infrastructure.

This excavated area was constructed as a stormwater retention area at Kirkland Elementary School. Author Michael Ellegood explains that the adjacent basketball court is a compatible use because the retention pond will be used only during storm events, when the court is not in use, and the area is expected to drain fully within 48 hours after a flood. If water flow does affect the court, its prestressed concrete construction should protect it from structural damage.

Again, a formal risk analysis should be conducted as a meeting of the project delivery team. Throughout the risk analysis phase, include documentation and follow up as appropriate, and continually review identified risks at each project meeting to assess their status.

The leading cause of project change requests and construction claims is delay.

For the contractor, time is money. For each day on a construction project, the contractor must pay crews, equipment rental, insurance, and other overhead costs. Thus, if a contractor is delayed, costs escalate, and the contractor will seek financial relief, usually in the form of a construction change request. Common causes of contractor delays are:

- Weather: It is common to specify the number of rain days in the plan assembly. This specified number is contained in the base contract; if they are exceeded, the contractor may request a contract change.

- Delayed responses to requests for information (RFIs): An RFI is typically initiated by the contractor to obtain clarification on the design plan. Typically, the designer does not have staff dedicated to receiving and responding to RFIs. Instead, the design team has moved onto a new project and now must take time away from it to research and respond. Thus, RFIs must be logged and managed with follow-up as appropriate. The contract with the designer for construction services should specify the days allowed for response. Often, phone questions are permitted if properly documented. Provide an audit trail of RFIs and a contemporaneous project history.

- Delays in reviewing and responding to shop drawings or material/equipment substitutions: Some aspects of the project may require “shop drawings,” detailed designs to augment the original plans. For example, the HVAC designer might specify an air handler of a certain size and capacity. The contractor procures the air handler unit, but now it needs to be provided with power and placed on a platform that will support it and still provide access for maintenance and component replacement. These will be detailed in shop drawings prepared by a subcontractor. The shop drawings, in turn, must be reviewed by the original designer to assure compatibility with the rest of the building and the designer’s intent. This review may take time and can result in contractor delay. As above, times and documentation should be specified. Close review of shop drawings is critical. The infamous 1981 Hyatt Regency walkway collapse is a classic case of a contractor changing a design, submitting a shop drawing reflecting the change, and having the designer approve it unwittingly.

- Material, labor, or equipment-related delays: Any one or combination of these can cause delays, but they are typically the responsibility of the contractor and should not cause a contract change.

- Other causes of contractor change orders are owner requested changes, “unforeseen conditions” (often underground surprises), vague or misinterpreted plans, and expedited schedule requests.

Best practices in change order management

My recommendations:

- Do no work without an agreed-upon change order—a signed addendum to the base contract. Advise the contractor at the project outset not to do any work that is not specified in the base contract.

- Identify the roles and responsibilities of each member of the project delivery team including the contractor, designer, owner’s representative, and inspector. Advise the contractor not to take direction from anyone other than the owner’s representative.

- Identify what is not included in the contract.

- Where possible and practical, identify unit prices in the base contract. For example, consider the estimate that providing water to a building requires the contractor to provide 300 feet of one-inch water supply line. During construction, it is found that 320 feet are needed. If the contractor provides a unit cost of $210/foot, calculating the additional 20 feet is easy.

- At every project meeting, ask the contractor, “What is owed in terms of information?” and, “Is there a delay for any reason?”

- Maintain close and continuing communications with the contractor and the design team.

- Maintain contemporaneous records of work done, weather, site conditions, and so forth. Augment the written record with photographs.

- Recognize that change is inevitable and budget for it. Ten percent of the contracted construction price is a rule of thumb for the average project.

Back to Kirkland

The first article of this series used the design and construction of a 6,000-square-foot classroom building in Kirkland, Arizona (an actual and ongoing project) to illustrate the importance of a comprehensive project initiation process. This project, though small in scope, had known knowns, known unknowns and unknown unknowns that caused more than a few surprises. These will be examined as a case study in risk analysis and change management.

Kirkland Elementary School serves fewer than 100 students ranging in age from kindergarten to 8th grade. It is in a rural location, a 53-minute drive to the nearest town for shopping, medical services, and amenities. It is also quite economically impoverished, with a total assessed property valuation in the entire school district of less than $1,000,000. Three-quarters of the students are on free or reduced lunch, and a significant percentage of students are reportedly from families with one or more parents incarcerated or on probation. There is no educational alternative for these students except possibly home-schooling.

The original school building was constructed in 1919, with two additions added in 1972. During the past decade, three devastating floods closed the building for extended periods and caused a half-million dollars in emergency repair work. Given the age and condition of the building and considering that it would still be subject to flooding, the decision was made to construct a new building elsewhere on the campus and to dispose of the old building.

The project started with a series of known knowns:

- Construct a 6,000-square-foot classroom and administrative building.

- Construct the building on the existing campus but out of the immediate flood hazard zone.

- Equip the building with:

- Four classrooms plus a kindergarten classroom and a pre-K classroom

- An administrator’s office

- A workroom with file space and office machines

- A nurse’s office

- A secure reception area

- Four restrooms

- Construct flood control facilities to channel and detain storm water.

- Provide safe and proper access for school buses, pedestrians, and vehicles.

Then, early in the project, some known unknowns became apparent:

- The soil in the area that flooded was contaminated with human waste, requiring mitigation. (Several years prior to the flooding incident, a previous administration allowed the installation of a septic tank and drain field upstream of the classrooms.)

- The proposed site for the new building had a power pole located directly in front of the intended front entrance. This needed to be relocated.

- The proposed site had numerous underground utilities that had to be relocated or removed.

All of this required investigation, coordination with utility companies, and a probable increase in work scope.

As the project neared construction, there was also a major and costly surprise: an unknown unknown. During the county’s plan review and permitting process, the fire marshal required the installation of a 30,000-gallon water storage tank for fire suppression. This is an NFPA code (NFPA 1142 and 1403) requirement for rural, well-dependent water systems. In addition, the fire marshal required that the tank be located in front of the school (visible to all) and have special fire department connections, cathodic and lightning protections, and a supply line. Providing the tank would require a structural foundation, electrical supply, water supply, and the manufacture and installation of a steel tank manufactured to NFPA 22 standards. No one on the project delivery team was familiar with this 2022 code requirement until it was flagged during the final plan review prior to permitting. This added approximately $680,000 to the project cost.

As this real-life example shows, facilities leaders should keep in mind the admonition of Donald Rumsfeld and the existence of those known knowns……known unknowns……and unknown unknowns. A rigorous risk analysis protocol can help mitigate these surprises.

Coming in the May/June Facilities Manager: key construction details.

Michael S. Ellegood, P.E., is a practicing civil engineer, a former senior executive of major international engineering firms, and a former large county public works director. He serves on the Arizona State School Facilities Oversight Board, the state agency charged with overseeing all public-school construction in Arizona. An experienced project manager, he has published articles and conducted training on project management. He can be reached at [email protected].