The era of “healthy buildings” has arrived. Even before the COVID-19 pandemic, building owners increasingly recognized the bottom-line benefits of implementing measures to optimize indoor air quality (IAQ) and other critical environmental measures. While COVID may not have created this trend, it has certainly given it high-profile momentum.

The requirements for creating healthy buildings are familiar to universities and other institutions that house high-end laboratories. After all, for years labs have focused on this element of health and safety. Initially, the emphasis was on lowering energy usage in labs, then came the push to improve safety through both enhanced ventilation and monitoring of all issues. Most recently, overall IAQ has been the hallmark of the next-generation laboratory.

Facilities leaders who manage these lab environments now have a new challenge: They must take that expertise and apply it to all the other spaces on a university campus—the classrooms, dining halls, and student unions. The IAQ measures and other sophisticated protocols used in labs for the past 15-plus years are now required in a university’s nonlab settings.

In a post-COVID world, lab techniques apply campus-wide, and all areas should be considered critical spaces.

Beyond Energy Savings

Historically, labs were always the highest energy user of any building on a campus. That’s why, early in the development of modern labs, the focus was on lowering their energy usage. Lab managers from the 1980s and ’90s can surely recall the push to make labs more energy efficient. This represented a move away from the “constant air volume” design approach that pumped fixed amounts of air into the lab—and out of the fume hoods—to a “variable air volume” (VAV) design approach. The VAV approach varied the amount of ventilation air delivered to the lab based on what was required for the fume hoods to operate safely, while also satisfying the temperature requirements. This is a much more energy-efficient approach that still maintains the required safety in the lab.

The leading manufacturers of laboratory control systems (LCS) entering the market at that time took labs to the next level of savings by implementing the VAV approach. This enabled energy managers to meet their energy goals by using significantly less air in labs. If any issues or chemical spills occurred in the lab, the lab manager or researcher could promptly direct more air into the lab via an emergency override button. This reinforced the oft-used motto: “The solution to pollution is dilution.”

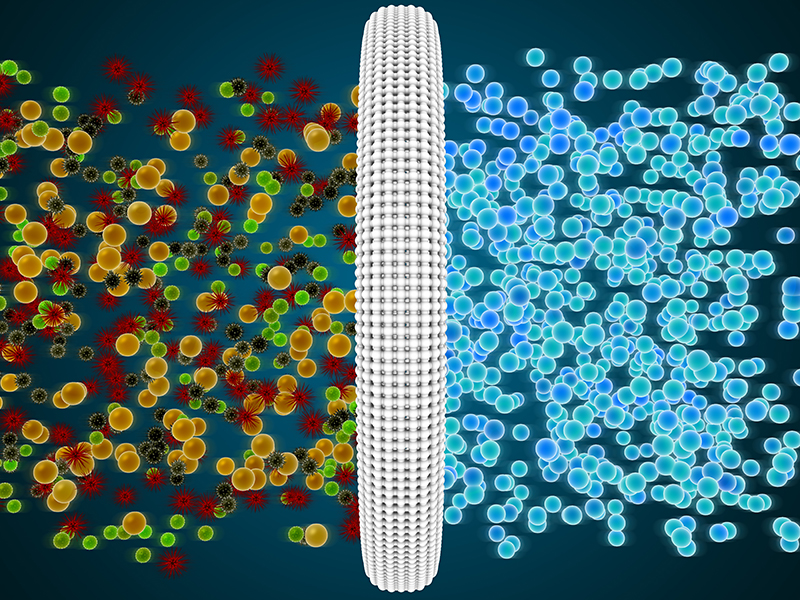

The next-gen laboratory system now integrates air quality monitoring of the lab air in order to provide the optimal amount of ventilation air for safety while not over ventilating the lab and wasting energy. This solution makes the lab even more energy efficient and also provides dashboards with key analytics to provide additional layers of safety, including notifications when something in the lab goes awry. Such features ensure correct protocols for properly handling chemicals, for example, and other steps to protect researchers and students.

Energy, safety, and better IAQ eventually became the next-gen approach for operating labs. These new technologies and applications didn’t replace the previous controls—they enhanced them. By integrating with the existing systems, these new techniques ushered in a new era of energy savings and safety.

What’s more, this evolution enabled web access to this information by anyone with proper credentials. Instead of housing it all in a central control system that only a few people could view, data became broadly accessible. By opening that information access, teams from the environmental health and safety (EH&S) department, deans of research, and lab managers can all have insight into what’s happening in the lab from a safety and IAQ standpoint. Sharing information in this fashion has facilitated collaboration between various departments when troubleshooting problems.

The COVID-19 Effect

In the wake of the COVID-19 pandemic, people are more concerned than ever with IAQ. That obviously includes labs, where safety is always a driver because of the possible presence of chemicals or particles in the air. Lab managers must make sure that all research is done in the fume hoods; if there are particle or chemical events outside the hood, however, there is a system in place to increase ventilation air and maintain a safe operating environment. Plus, providing data when this event happens allows EH&S to know when and where these events occur and to take corrective action.

Outside the labs—in buildings across the campus—these protocols should serve as a template. Even nonlab spaces are now considered critical, and everyone is concerned about IAQ, so we must apply to nonlab spaces what we’ve been doing for years in labs. In short, nonlab buildings should be emulating labs by doing the following:

- Integrating all IAQ information into the building management system (BMS)

- Bringing the correct amount of ventilation air in, when and where needed, based on various measured parameters

- Continually measuring and communicating IAQ parameters to all interested parties via a cloud-based interface

- Potentially increasing the level of filtration of the supply air, and

- Possibly implementing additional cleaning strategies.

If you’re a lab manager, technology that initially targeted energy savings now delivers very real ROI from both health and safety perspectives based on the information we now have about the actual IAQ in labs—and this technology also applies to nonlab environments on your campus.

The issue is about more than just energy—it’s also about better IAQ and about providing a healthy building environment for your faculty, researchers, students, and employees!

Peter Hmelyar is vice president of sales at Aircuity, Inc., in Wheaton, IL. He can be reached at [email protected]. This is his first article for Facilities Manager.

Perspective on the Profession

Provides opinion and commentary on aspects of education administration, funding, and campus facilities management. To contribute, contact [email protected].

See all Perspective on the Profession.