“The future is already here. It’s just not that evenly distributed.” — William Gibson

The smart building concept first appeared in the early 1980s and was defined as “a marriage of two technologies — old-fashioned building management and telecommunications.”i In the past few years, the building industry has developed advanced applications at the intersection of building information modeling (BIM), artificial intelligence (AI)-informed data analytics, and Internet of Things (IoT) technology. Today, that integrated dataset—drawn from the physical asset (the building) and a virtual asset (the model)—can improve facility operations by providing precise real-time data feedback using a set of integrated applications known as digital twins.

Dr. Michael Reid, chief scientist for advanced manufacturing at the Florida Institute of Technology, introduced the concept of digital twins at the American Society of Mechanical Engineers conference in 2002. Later research expanded the definition for applications in the built environment, delineating a digital twin as “a realistic digital representation of physical assets, distinguishing itself from other digital models due to its connection to the physical twin.”ii

REALIZING THE POTENTIAL FOR DIGITAL TWINS

A digital twin leverages intelligent data and devices (i.e., network-based building management systems, energy performance management systems, audiovisual (AV), information and telecommunications technology, and security systems, embedded occupancy sensors, physical asset Radio Frequency Identification (RFID) tags, and Bluetooth beacons) that are integrated with the building model. Implementing digital twins helps designers, engineers, contractors, and manufacturers create better buildings through embedded system intelligence, providing a digital feedback loop and improving building owners and managers’ operational and cost efficiency and goals for sustainability and resiliency.

Considering those definitions, imagine a digital twin of an entire facility with connected data from roof membrane sensors to HVAC; electrical, and plumbing systems, to lighting; AV systems, and security access controls to occupancy loads; and staff and equipment location tracking. The digital twin updates itself, providing feedback on changes according to an established baseline.

Using a 3-dimensional model and real-time data dashboard, a building manager could view areas where building systems are aging or faulty and make improvements. AI-assisted analytics could predict operational needs before any system failure. Multiple digital twins could be integrated across an entire campus, expanding the potential for a holistic view.

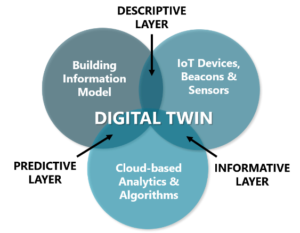

Figure 1–Digital Twin Layers

There are three interconnected layers of data in a digital twin design [See Figure 1]:

- Descriptive: The editable design and construction data, illustrated in BIM, with data links to physical assets—the equipment, systems sensors, and spaces that comprise the facility.

- Informative: Includes operational and sensory data. Based on real-time connections, the model becomes informed and linked back to the physical asset.

- Predictive: Provides the dashboard with visual data providing operational insights. As the digital twin evolves, algorithms allow simulating future scenarios to address what-if scenario questions.

Each layer has integrated AI, supporting interoperability, analytics, and defined use cases. The digital twin’s value comes from the ability to draw insights into future maintenance and servicing needs and improved operational efficiency by recreating a building with a virtual model that includes all relevant spaces, equipment, and systems.iii

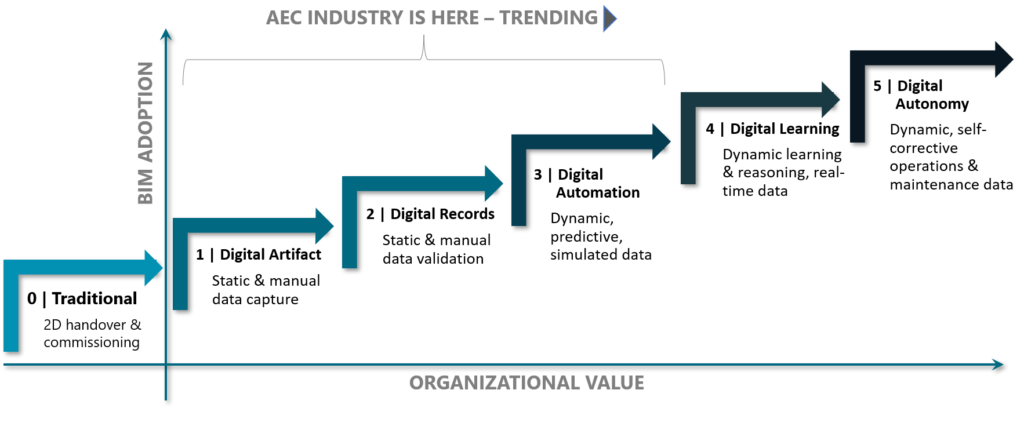

DIGITAL TWIN MATURITY

The architectural engineering and construction (AEC) industry has moved from traditional 2D design, construction, project closeout, and commissioning to a digital approach based on 3D building information modeling [See Figure 2]. As-built documents are now at a stage where project data capture is a digital artifact based on a static, virtual, as-constructed model supported by other digital document records. The next stage of development of digital records still requires a manual validation of dispersed data (i.e., asset databases, building management, life-cycle management, and data from similar computer-aided facilities management systems) and other asset database records. Digital automation—dynamic predictive, automated, and simulated data—is based on assessing historical and trending data.

Figure 2 – Digital Twin Maturity Model (Source: G. Broadbent/Microdesk)

Soon, digital twins will incorporate digital learning—dynamic, reasoning, and comprehensive real-time data, and bi-directional, evidence-informed machine learning—to aid human decision making. The final step in digital twin maturity is digital autonomy—dynamic, self-correcting operations and maintenance—based on multi-directional, real-time IoT feedback and AI-decision engines.iv As digital twins mature, new visualization tools like augmented and virtual reality allow operations staff to interact directly with the virtual model.

IMPLEMENTING A DIGITAL TWIN

A new digital twin project starts with the campus facilities design and operations staff setting clear goals and aspirations then engaging the design team of architects and engineers with contract language that defines the desired digital twin results. The construction manager coordinates the integration of the physical and data-connected systems. An analytics team implements the cloud-based computational software at the heart of the feedback loop to integrate with the virtual model and project dashboard.

In the AEC industry, resources from established companies like Autodesk, Archibus, and Bentley, along with newer entrants like Cohesion, IES, and Invacara, provide tools for those campuses interested in exploring the potential of digital twins. The nonprofit Digital Twin Consortium provides a forum for increasing the awareness, adoption, interoperability, and development of digital twin technology by supporting innovation and advising outcomes for end users.v

A HOLOGRAPHIC FUTURE

We are still in the early stages of digital twin development. Adoption requires a coordinated, holistic team effort, requiring the owner and project team to adopt new approaches to digital workflows and integrated delivery. Scott Stovall, Associate AIA, architectural designer at Clark & Enersen, commented,

“We are getting closer to digital twins every day. BIM technology can run analytical data (e.g., energy, lighting, structural loading, detailed geometry, etc.) as we push the simulation to fuel the feedback loop for design testing. A concept as simple as standardizing workflows provides real-time feedback in an iterative, cross-discipline, multi-phase design process, evolving from a simple model idea to a more granular, intent-based design grounded with real-time cost implications.”

With a bit of imagination, it’s not hard to see a near future emerging where innovators and early adopters develop digital twins on real campus projects and move both campus facilities operations and the AEC industry forward, making the vision of smart buildings a beneficial reality. Not quite a hologram (yet), but still very cool.

References

i James Sinopoli, Smart Building Systems for Architects, Owners and Builders, (Burlington, MA, Butterworth-Heinemann, 2010).

ii Rafael Sacks, Ioannas Brilakis, Ergo Pikas, Haiyan Sally Xie, and Mark Girolami, “Construction with Digital Twin Information Systems,”(published online by Cambridge University Press in Data-Centric Engineering, Vol 1, 2020), https://www.cambridge.org/core/journals/data-centric-engineering/article/construction-with-digital-twin-information-systems/C88A0AE68BBA09517D7534B9DBE24FEF

iii George Broadbent and Jeff Chen, “Digital Twins: The Future of Facility Maintenance & Operations,” Microdesk Webinar, June 21, 2021, https://www.youtube.com/watch?v=asMox4SA-as

iv Ibid.

v Tadeh Hakopian, “The Next Phase of IoT – Information and Visualization with Digital Twins,” Microsoft Developer Webinar, May 4, 2022, https://learn.microsoft.com/en-us/events/azure-cosmos-db-conf-2022/the-next-phase-of-iot-information-and-visualization-with-digital-twins

Craig Park is an associate principal and director of digital experience design at Clark & Enersen in Lincoln, NE. He can be reached at [email protected].

Technology + Trends

Seeks to identify technology and trends evolving and emerging in educational facilities. To contribute, please contact Craig Park, field editor of this column.

See all Technology + Trends.